China’s Cable Wire Recycling Machineindustry leader

-

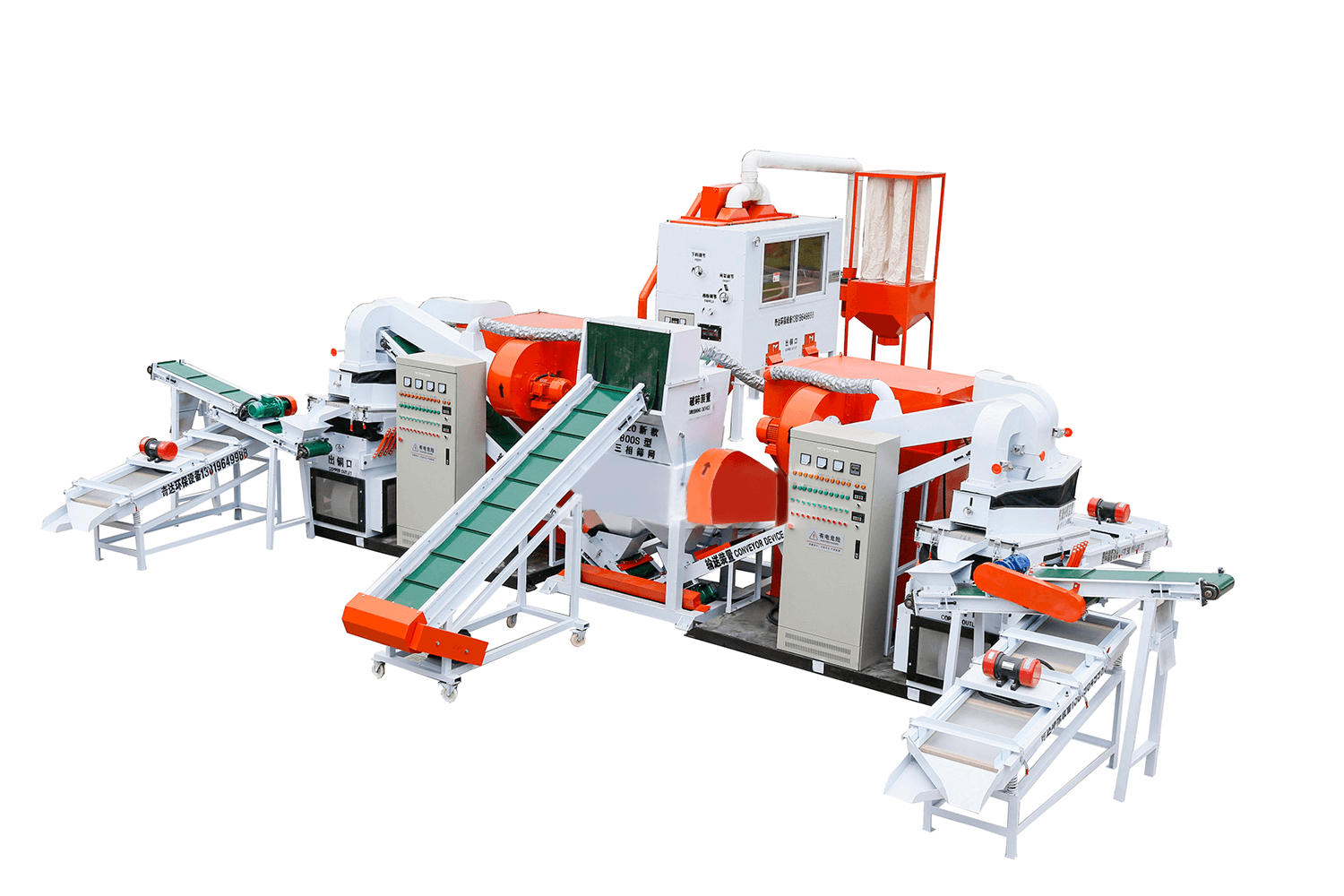

Cable Wire Recycling MachineDescription

- Materials used

- argument

- The working process of Cable Wire Recycling Machine

Cable Wire Recycling Machinen production:

Cable Wire Recycling Machine is a kind of equipment specially used for treating waste wire, cable, telephone line and electric route. Through the steps of feeding, crushing, vacuuming and separation, the copper and plastic are separated. The purity of the separated copper can be up to 99.9%1. The main components of Cable Wire Recycling Machine include feeding machine, crusher, chain conveyor, sorting machine, shaker and dust box .

Working principle

The working principle of iCable Wire Recycling Machine cludes the following steps:

feeding : The waste wire is transported to the crusher.

shredding : The wire is shredded into small particles through a shredder.

Vacuum and separation : The use of air specific gravity separator to separate copper and plastic, and by vacuum cleaning system to separate the two 2.

Advantages and application scenarios

Advantages of copper rice machine include:

high efficiency separation : compared with the traditional artificial way, the efficiency of copper rice machine is higher, the separated copper plastic is free of impurities, suitable for recycling, reduce the transportation cost of raw materials .

environmental protection and reliable : The equipment adopts assembly integrated design, easy installation, automatic cycle operation mode, environmental protection and reliable .

simple operation : The overall equipment operation is simple, only one manual feeding can complete the whole process .

The application of copper rice machine is very wide, suitable for metal recycling, waste treatment and mining fields. Whether it is a small factory, medium-sized enterprises or large industrial plants, you can choose copper rice machine as the preferred equipment

Dry Cable Wire Recycling Machine can handle all kinds of waste wire, such as square wire, communication wire, electrical wire, electrical route, cable, headphone wire, motor wire, optical fiber, power cable, high voltage cable, broadband line, transformer line, computer line, electromagnetic line, underground cable, is the main equipment for waste wire and cable processing.

(TXECHNICAL PARAMETER) | ||

加工范围: | Processing diameter | Φ0.2-Φ30mm |

SIZE | Overall dimension(LxWxH) | 720cm*750cm*220cm |

WEIHGT | Machine weight | 5800kg |

Motor voltage | Motor voltage | 380V/220V |

Output per hour | Output/hour | 700kg-1200kg |

POWER | Motor Power | 76KW |

The working process of Cable Wire Recycling Machine can be divided into the following main steps :

crushing link : The waste wire is first sent to the crusher, through high-speed rotating tools and other components, the original complete wire cut, broken into smaller particles. This process makes the subsequent separation operation easier to carry out, at the same time, a reasonable crushing force can ensure that the copper rice is not excessive damage, and the wire can be fully broken 1.

specific gravity sorting : the crushed material enters the specific gravity sorting equipment. The density of copper is relatively large, while the density of plastic materials such as wire leather is less. In the specific gravity separation equipment, the use of vibration, wind or water and other media, according to the different density characteristics of the material, so that the copper rice and wire skin in the separation area to show different movement tracks. The dense copper rice will accumulate in the lower part of the sorting bed or bin, while the less dense wire will float above or be blown to other areas to achieve separation .

electrostatic sorting : For particularly thin wires, there may be a small amount of mixing after specific gravity sorting. This is where electrostatic sorting comes into play. Electrostatic separation equipment will bring different charges to the material, copper rice and wire leather due to different electrical properties such as electrical conductivity, under the action of electrostatic field will move in different electrode directions, so as to further remove the residual wire leather from the copper rice, to achieve a cleaner separation effect .

dust removal : In the separation process, some impurities and dust will be produced. These impurities and dust are sucked into the discharger through the suction port, and then sent to the pulse dust removal device for dust removal treatment, to ensure a clean working environment

Cable Wire Recycling Machine FAQ

Cable Wire Recycling Machine is mainly divided into dry Cable Wire Recycling Machine and wet Cable Wire Recycling Machine.

Cable Wire Recycling Machine an hour output of 100KG,200KG, 300KG, 400kg, 500kg

1, all kinds of different size lines do not need to be sorted, can be put into the equipment at the same time, after grinding can automatically separate clean copper and plastic.

2, the whole set of equipment adopts platform combination design, customers only need to connect the machine after receiving the power can be used.

3, PLC control, uniform feeding, intelligent operation, can automatically adjust the front-end feeding frequency according to the back-end load, does not make the system shut down due to overload, simple operation, save time and labor.

4, wide range of application, wire diameter 0.5-30mm wire and cable can be used, the length is not limited.

5, grinding tool adopts alloy steel high hardness material, wear resistance and impact resistance, long service life.

6, the whole system seal work, multi-level dust filtration collection, does not pollute the environment.